What is Snow Den?

Everyday ambitious climatologists reside in one of the most volatile environments in the world -- the summit of Mt. Washington -- to observe and investigate weather and associated meteorological phenomena. My concept for Snow Den, the new summit observatory, reimagines the the existing Mt. Washington observatory, as a new scientific destination on the forefront of architecture and weather prediction.

The site, Mt. Washington, is known as Agiocochook or ‘Home of the Great Spirit’ to the Abenaki people, the mountain’s early inhabitants. The highest point of the mountain and home to the proposed observatory is 6,288 feet above sea level, along a treeless ridgeline called the alpine zone. It is on the north-west ridge of the Great Gulf—a large glacial cirque. The ridge is comprised of a bedrock lip and glaciated debris, has been shaped for thousands of years by wind and water erosion. The site is comprised of a large rock outcropping with pockets of hard pack soil, gravel and small amounts of earth cover such as alpine flora moss.

Redefining Shelter in Wind Driven Places

My concept for Snow Den, proposes the observatory and visitor center as an embedded cavern, cut into the windblown glacial till of the Mt. Washington summit. Snow Den borrows the basic principles of the snow bear den, native to the white mountain region — a burrow like shelter, in which hibernating bears spend cold winter months. During an early winter, the bear digs a hole on the slope of a snowdrift. The animal is subsequently covered by a thick layer of snow. The den floor is covered with a soft bedding of leaves or moss and small, rounded openings occur when the snow is thawed by the animals’ breathing. Dens can be located by these openings and the hoarfrost around them.

The mountain hollow I’m proposing, would be partially buried during winter months — like the bear den — to conserve thermal energy protecting scientists and visitors from the harsh winter environment. In winter temperatures range below 3 degrees Fahrenheit with a typical 30 mile per hour sustained wind with highly unpredictable and extreme conditions occur frequently, such as reduced visibility to 3 feet from cloud cover, white-out blizzard conditions and powerful hurricane force wind gusts. A record wind speed of 231 miles per hour was recorded at the summit in 1932.

Discovering Efficient Form

Snow Den takes the most efficient form in the wind driven environment. The shape of the summit is the direct result of the efficiency of matter. The prevailing wind flows up along the walls of the glacial cirque and deposits snow of the leeward ridge forming a cornice, the roof of the Snow Den follows this form. The roof line of Snow Den, represents this natural flow, easing friction and pressure during high winds. The den carves into the crest of the high alpine garden. In harmony with nature, this subtle gesture gives Snow Den the ability to disappear into the cornice during the winter months.

Bending a Tradition of Modern Architecture

Following some of the principles defined by Frank Lloyd Wright --the Snow Den concept re-interprets mid-century modern ideas with curvilinear form. The design embraces nature through vast spans of glass capturing views of the surrounding landscape as focal points throughout the building blurring the barriers between indoor and outdoor living. A centralized light well, terrarium lets in extra light while providing occupants the opportunity to go outside to get fresh air protected from the wind. The terrarium, is filled with moss and other native plant species; which are endemic to alpine meadows in the White Mountains and outliers of larger populations in arctic regions far to the north.

Split and multi-level open spaces are essential in mid-century design. The Snow Den footprint is pure topography with multiple, open staircases, partial walls, open stairs, varying ceiling heights and carefully scaled environments,

Using a Topographical Landscaped Floor Slab

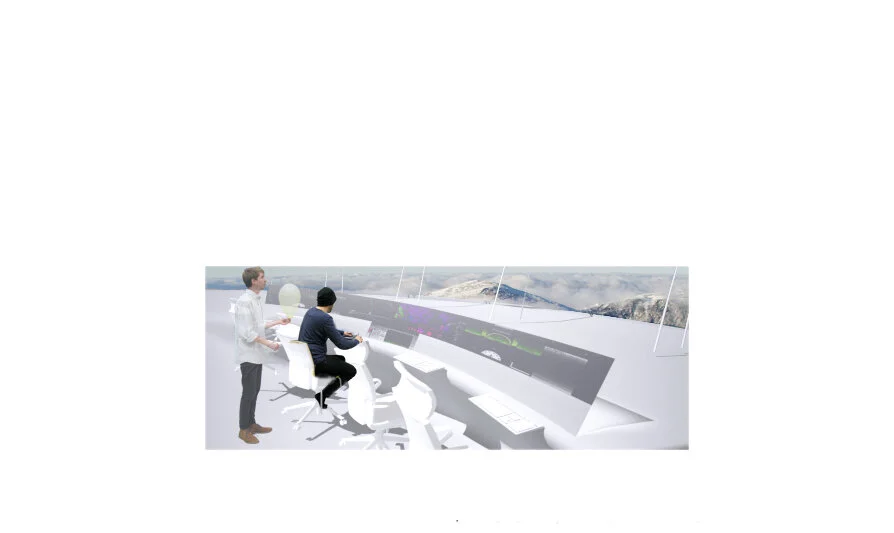

The entrance corridor ramps down to a sunken central floor area, with integral slab topography including three levels: a seating area, a bench, and a work-zone. The south edge of the low area -- an area for lounging -- ramps up like a real, earthen embankment. A central micro-pellet furnace rises from the center of the sunken floor. The work-zone and/or observation deck, is situated along the exterior edge of the lower level while the upper floor becomes the desk and monitor panel for the scientists. Much like the flight control deck, the observation deck is where researchers analyze the atmospheric phenomena and interpret meteorological data.

At the tunnel entrance, is a server room called the Air Lab. It contains weather data processors receiving information from local air stations, satellites, and radar. The lab is enclosed by a semi-transparent, glass, led display board, projecting floor to ceiling diagrams of weather data for scientists and visitors to observe.

Learning from the Abenaki

The sleeping quarters are located in the southern-most chamber, the location and perimeter glazing absorb solar heat gain throughout the day to keep the sleeping quarters warm. The glass, structural curtain wall at the perimeter contains triple glazing for insulation, in addition to several operable openings for fresh air.

The layout of the sleeping chamber is inspired by the domed room dwelling used by the region’s indigenous Abenaki, called the ‘Wigwam’. The Snow Den chambers, like the Wigwam, are segments within a round space surrounding a central heat source. In this case, the heat source is an enclosed micro-pellet furnace; partitions radiate outward from the center furnace to separate the bunks for privacy. How will we encapsulate the furnace and how is it fed? Perhaps we will have to fully enclose it like a radiator and insert the fuel pellets from the crawl space below. Innovation is necessary here.

Building the Future with 3D Printing

Using additive manufacturing in building construction has already begun in other parts of the world, we are hoping to employ this on-site technology to fabricate the Snow Den shell. There are a number of benefits to using 3D print in building construction. The first advantage, is that this technology can produce complex forms that would be difficult and wasteful — and in some cases impossible — to make without print technology. If constructed using more traditional construction methods, Snow Den, an organic form, would require the use of Styrofoam form work — a time and energy consuming process that would result in a large amount of waste. Instead, an industrial sized 3D printer will be brought in pieces and assembled on site. The printer, which will rest on a secure framework -- much like horizontal scaffolding -- will take approximately 10 months to print Snow Den in place given technological advancements are complete in 4 years. Winter conditions such as temperature and wind, do pose a problem for print construction, so the work will take two summers to complete.

Snow Den will be printed with a form-optimizing SSC based concrete, specifically manufactured for additive technology use. However, we are also interested in exploring other site and regional based alternatives. Might we break down and reuse concrete from the existing building? Could we use the gravel and sand excavated for the footprint? Almost any material can be combined with a binder and printed; sawdust, tires, sand, glass or metal, and post-processed materials. Print materials are made of 2 parts: aggregates which are the fill, and binders which are essentially the glue that holds the fill together. Finding the right binder for the aggregate is the most important part of the process and all material must be tested prior to construction to ensure optimum performance. Someday, we will see regional specialization simplify the material selection process; aggregates and binders will be predetermined and available per region. Our hope is to begin testing site-specific aggregate with binders now to evaluate the potential use of local material in lieu of concrete. We want to identify the most promising combinations and have them tested for use on Snow Den, so that materials are ready for construction in 4 years.

Snow Den was submitted to the Boston Society of Architects UNBuilt Award program.